Printed Electronics & Sensors

Recent progress in functional inks printed on various plastic substrates allows the development of innovative electronics devices that fit in Internet of Things (IoT) and smart electronics fields. Their disruptive properties such as flexibility or even stretchability, their adaptability and their lightness, provide a significant added value in terms of business benefits. Martin Technologies supports you to define your project, from the specifications to the market.

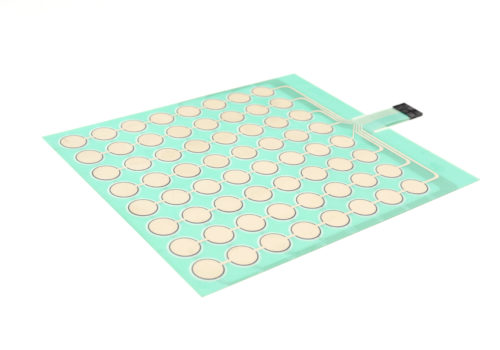

Force sensor or Force Sensing Resistor (FSR)

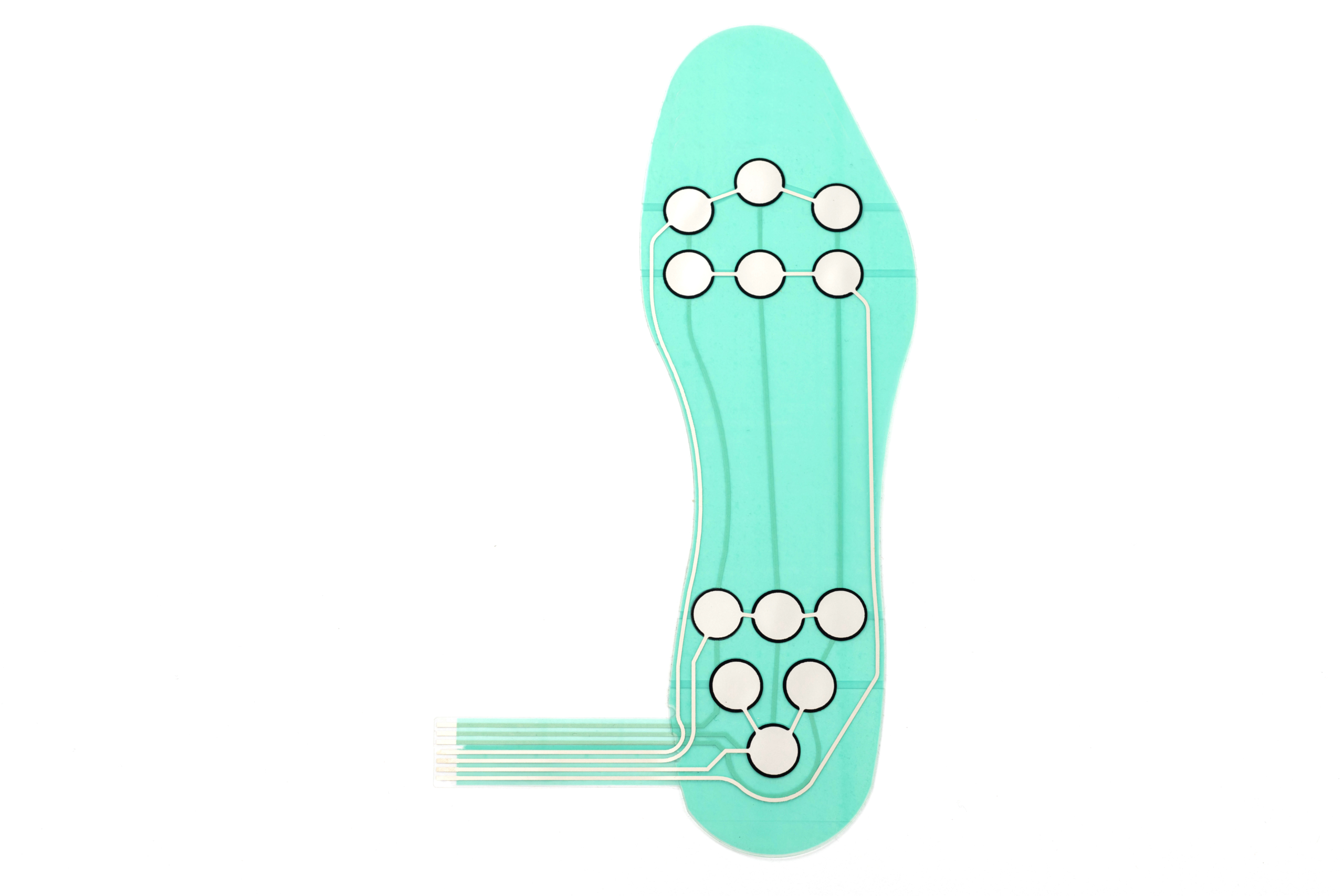

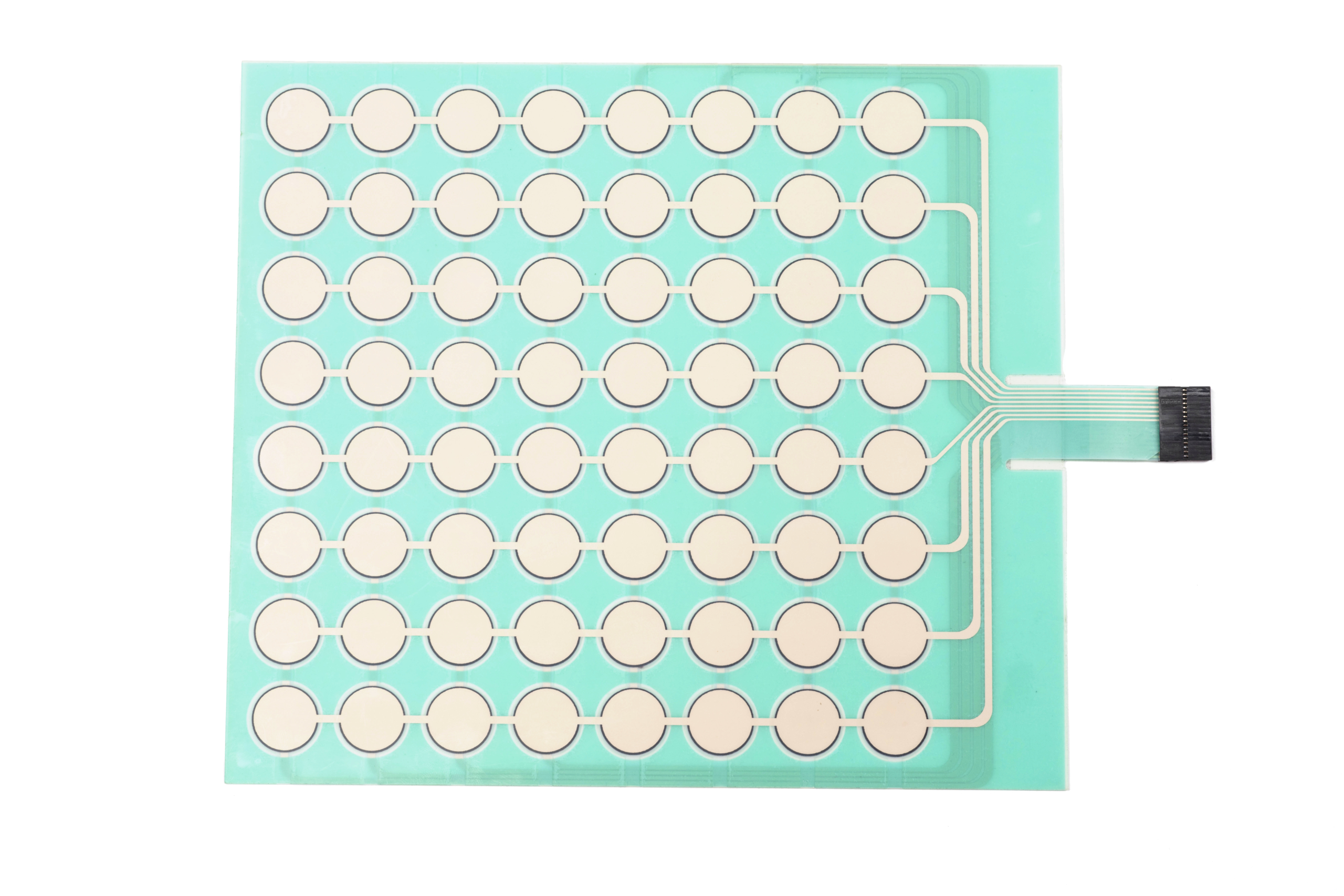

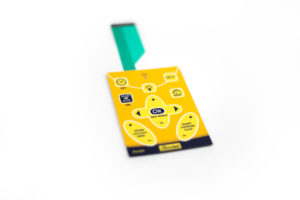

Force sensing resistors (FDS) exhibit a high variation in resistivity when pressure is applied. They consist of thin flexible layers fully screen-printed on plastic substrate (PET). As the pressure increases, their electrical resistance decreases and then returns to its original value when the stress is removed. The aim of this technology is to measure the force applied to a specific area and transmit to a particular electronic. They can be used as a tool to localize stresses within a surface.

Force sensors configurations

Force sensing resistors are manufactured from carbon-based piezoresistive ink with high electrical resistance. Their performances can be adapted through the ink formulation and device design.

What features for Force Sensing Resistor (FSR)?

- Measure force / pressure / weight

- Evaluate speed of stress

- Visualize contact between surfaces

- Know if a critical threshold is exceeded

- Map the stresses over a surface

What uses for Force Sensors?

FSR are very interesting tools in several industrial fields in particular for healthcare, transportation, sport, automation… Some applications are listed below :

- Pressure ulcers prevention

- Seat / bed occupancy

- Prosthesis placement

- Sport performance monitoring

- Robotic

- Infusion pomps

- Motor / Tool speed control

- Musical instruments controller

Printed flexible heaters

Thin and lightweight, printed flexible heaters are based on functional screen-printing inks. When current flows through the resistive inks, the device exhibits heat thanks to Joule’s effect. This technology provides the possibility to manufacture wearable and conformal products. They can be integrated into tight spaces and complex shapes and thus grant new possibilities.

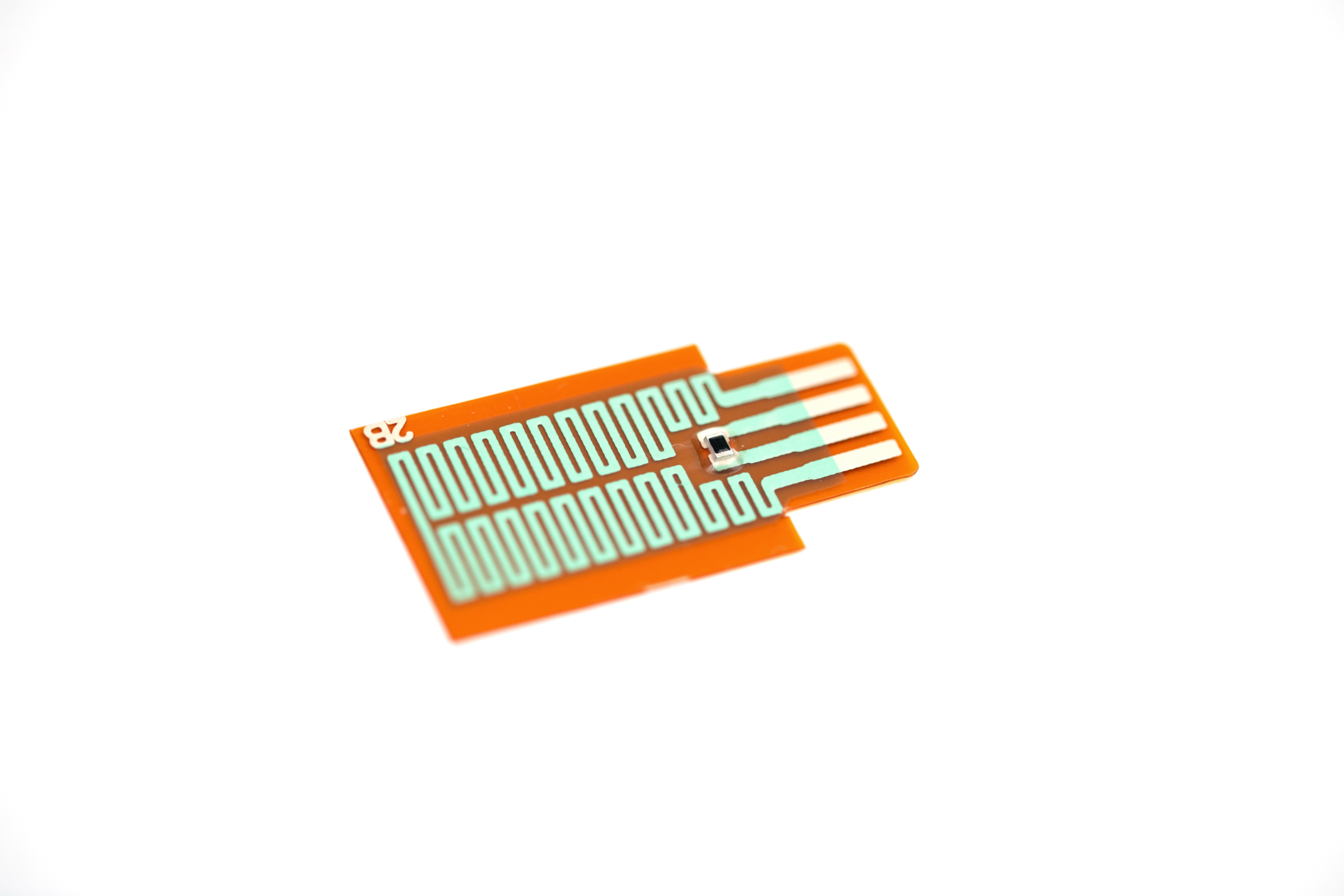

Fixed resistance heaters

Theses heaters are fabricated from a silver-based resistive ink printed on flexible plastic substrates (PET or Kapton). The resistance of the pattern varies slightly when activating the device. The temperature released by this element can be modulated according to the electrical resistivity, the design and the voltage injected. They are used in the 30-110°C temperature range.

PTC heaters

PTC heaters stabilize to a desired temperature depending the pattern. Unlike silver-based heating elements, their electrical resistance highly changes when the device is turning ON and allows to steady the temperature between 40 and 60°C. Their configuration comprises self-regulating carbon-based PTC ink printed onto silver conductive busbars.

Applications for flexible heaters ?

- Heated seat / bed

- Heated shoes / insoles

- Floor / wall heating

- Batteries protection

- Heated gloves

- Defrosters

- Biologic specimens storage system

- Sterilization or cleaning

- Sensor temperature stabilization

Flexible Hybrid Electronics (FHE)

The installation of SMD electronic components on flexible substrates allows the use of advantages of conventional electronics and printed electronics maintaining a high level of reliability. Thus, the attractive properties of printed electronics such as flexibility, lightness, conformability, thinness and low cost is combined with those of conventional electronics.

At Martin Technologies, these solutions are implemented using a screen-printed flexible circuit where components are deposited by pick & place technology.

Which components can be integrated?

- Resistor

- Thermistor

- Diode

- Transistor

- LED

- Capacitor

- Optical detector

Contact us

Your request concerns