Specialist in industrial marking

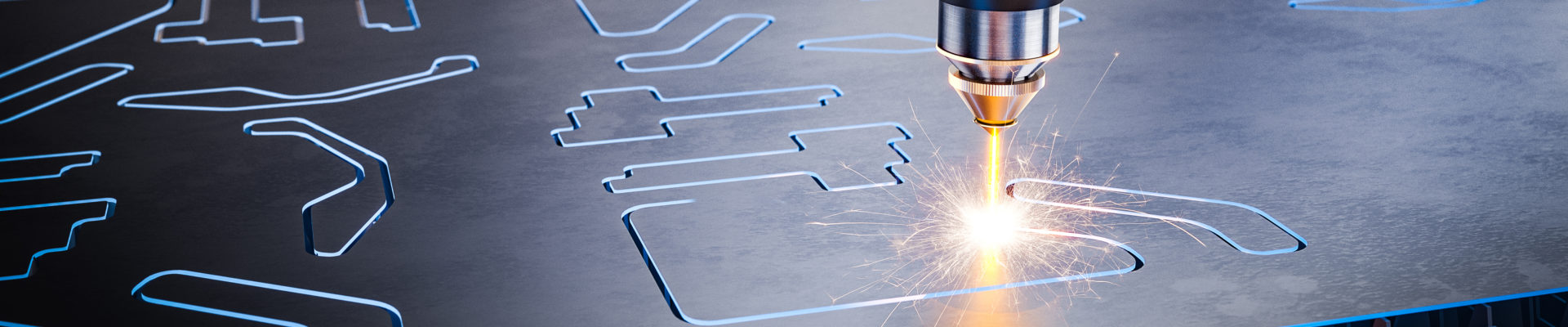

Martin Technologies is a leader in the field of industrial marking on plastic and metal (metal labels, nameplates), the design and manufacture of membrane keyboards and front panels, and the production of sheet metal components and machined parts.

Our products are designed for industry and communications, from one-off pieces to large-scale production runs. The company was founded in 1929, now has 100 employees and is based near ANGERS (49).

A controlled process

from A to Z

We are unique in that we control all our manufacturing processes. From the preparation of the raw material, the various surface treatments, the decoration of the part, its cutting… more than 50 trades are represented in the company. This major advantage gives us consistency in our production, quality control at every stage and control over our lead times.

Research

& development

A dedicated team for your customised projects. We study every request, and our design office is there to support and advise you, from concept to production, whatever the technical challenge.

Our values

Respect and kindness

Respect and care for our ecosystem (employees, partners, environment, etc.).

Trust and transparency

Trust each other by being transparent, honest and authentic.

Freedom and responsibility

We are responsible for our actions and for honouring our commitments.

Requirement

The high quality expected by our customers requires us to be exacting and rigorous at all times.

Join us

Want to be part of the adventure? Working at Martin technologies means giving meaning to your professional commitment alongside passionate colleagues. Because innovation and personal development are key values for our company, we’re always on the lookout for new people who can bring a fresh perspective to our business.

Contact us

Your request concerns